Polyurea is a chemical high-strength, ultra-high-strength elastomeric barrier coatings that form an elastomeric membrane that offers solid protection against accidental spills.

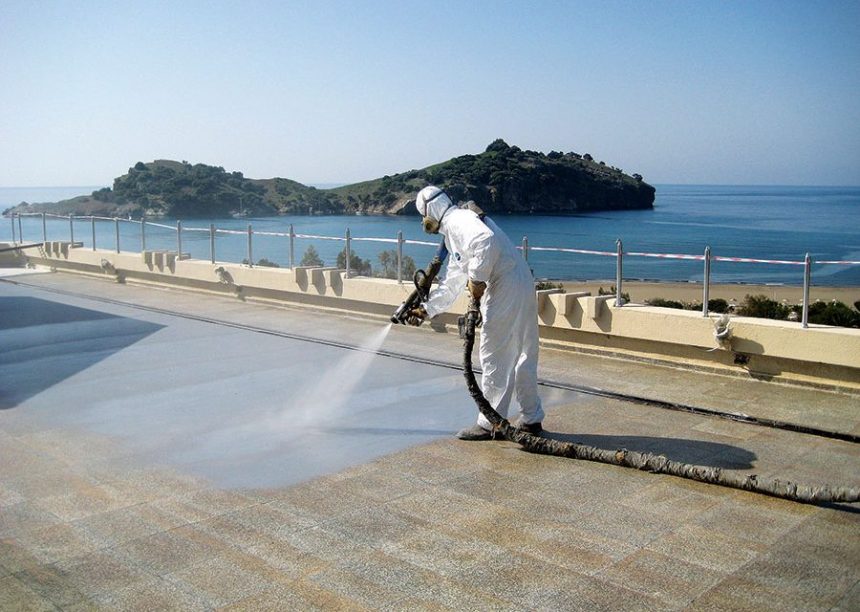

Chemical-resistant polyurea coatings offer strong resistance to acids, hydrocarbon alcohols, wastewater, and many other chemicals. They are eco-friendly (no VOC) quick-cure (fast-set) coatings that provide a rapid return to service that can reduce the time spent in downtime. The coatings are sprayed onto a variety of substrates, including concrete and wood, metals, geotextile fabric polyurethane foam, and many more.

Chemically Resistant Polyurea Industrial Coating Solutions:

ArmorLiner The Chemical Resistant Polyurea

GASOLINE CRUDE OIL ETHANOL & METHANOL

ArmorLiner- Features, and benefits:

superior chemical resistance to various acids, alcohols, hydrocarbons, waste, etc.

– A highly effective Barrier coating used for primary secondary and secondary containment

Purchase the liner only once! The resilient polymer can stand up to multiple spills.

is eco-friendly and contains 100% solids and contains no VOCs or solvents

Good elongation capable of moving in conjunction with substrate expansion and contraction

Speed-set elastomer for a quick return to service in order to reduce expensive downtime

Seamless, tough membrane. There is no seam or mechanical fastener weak points.

Why should you install Secondary Containment Polyurea Liners?

Secondary containment is the containment of toxic liquids (chemicals or hydrocarbons, wastewater, and more.) to protect against leaks or spills that could pollute groundwater, soil, and other components of the natural environment. spills of dangerous liquids can be harmful to public health.

It is the United States Environmental Protection Agency (EPA) has established a Spill Prevention, Control, and Countermeasure (SPCC) program that requires facilities that store huge amounts in petroleum and chemical items to establish a strategy in place to effectively contain spills. Selecting the correct secondary containment lining technology will add a layer of protection against accidental spills as well as significant EPA fines.

ArmorThane installs chemical-resistant industrial coatings which are used to protect infrastructures that are used in Oil and Gas, Mining, Wastewater, Power Utility, and a variety of other global industries. These ultra-high-strength elastomeric barrier coatings make a seamless monolithic membrane that offers reliable protection against hydrocarbon spills. The chemically resistant polyurea coatings offer a solid resistance to acids, hydrocarbon alcohols, water, and a myriad of other chemicals. These environmentally-friendly (no VOC) quick cure (fast-set) coatings provide a rapid return to service which reduces the cost of downtime. The coatings are able to be sprayed on a variety of substrates, including concrete and wood, metals, and geotextile fabrics woven into polyurethane foam and numerous other surfaces. Polyurea is a seamless membrane that can be applied to a variety of surfaces and is able to conform to any shape, thereby reducing the possibility of liner leakage. Flexible, high elongation properties permit the coating to change shape with the substrate expanding and contracting due to thermal changes in temperature.

Nowadays, storage tank facilities are typically controlled by periodic inspections, reports, and certificates issued. If storage tanks are at an endpoint in their life, polyurea can bring them back into functional and usable condition. The benefits of the SPI’s polyurea protective coatings can extend the durability of the structure for a fraction of the cost of replacement.

Get in touch with ArmorThane today to find out more about our world-class secondary containment along with primary containment lining options.